OPERATION

For switchable PDLC film, the structure: PET with ITO coating +Liquid Crystal layer +PET with ITO coating ,it is different with other normal window film, so when you operate, you need pay attention , pls check the following our instruction,maybe help you to operate.

Switchable PDLC Film Storage:

The storage environment: -10 – 50℃ ,indoor ,dry and neutral air;

For roll type film, put on shelves like pictures:

For sheet type film, flat on table;

Film Handle Method :

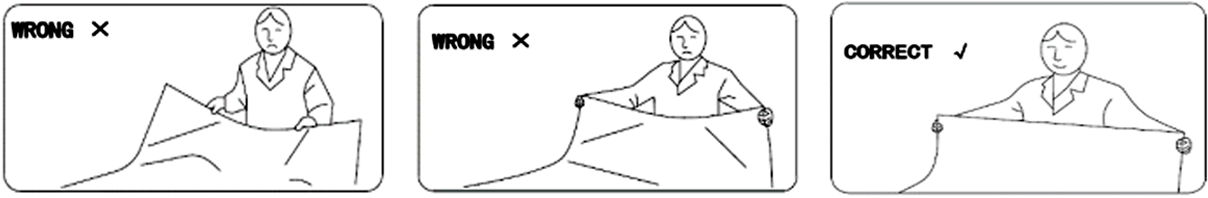

Film Cutting:

normally pls use rolling cutter to cut the switchable PDLC film,pls check the following instructure;

If you don’t have the rolling cutter, you can use scissor to cutter the film, but don’t use knife normally

Hinge and hole operation:

How to make the handle hole or fixture cutout, pls check the following youtube website:

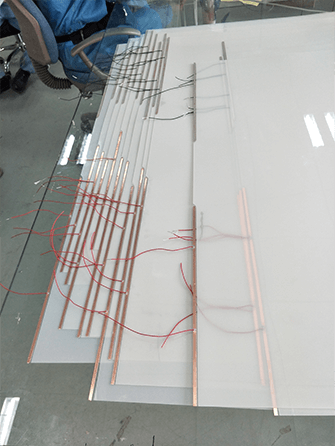

Busbar installation

The switchable PDLC film need busbar to run, Pls do the busbar based on the following instruction;

Self-adhesive Film installation

For the switchable self-adhesive film, the adhesion is not strong, just self-adhesive function, no special glue, it is different with other window film, So before you install the film, pls read the following items carefully!

Main step:

1. prepare the tool and material;

2. open the package to check the film;

3.clean the glass surface and film;

4.stick the film from top to down, or from one side to another side;

5.test the film with power;

6.seal the film edge and busbar position;

Laminated smart glass production process:

For switchable PDLC film, you can laminate with EVA to make smart glass, whatever you use laminated oven or autoclave machine, you can laminate the PDLC film, the laminated smart glass structure: glass+EVA+PDLC +EVA+Glass,if you want know detail pls contact with us;

Process:

1.prepare the glass and film;

2.assemble the glass and film:glass+EVA+PDLC+EVA+Glass;

3.Move to the laminated oven or Autoclave;

4.Use the laminated datasheet to laminated;

5.Test;

6.Pakage;

How to choose EVA film:

1.Low temperature, our PDLC film max temperature:130degree, EVA production meet that;

2.Neutral type,no acid or other corrosive, otherwise will damage the PDLC film;

3.Zero shrink, or lowest shrink

4.High transparent,lowest haze;

STAY IN CONNECTED WITH INNOGLASS

Sign up to receive our newsletter and exclusive discounts and offters.

NAVIGATION

Tel: +86 186 6026 2952

Email: info@inno-glass.com

Skype: chinafirstglass

WhatsApp: +86 186 6026 2952